Robert Yokel’s Experience with Occam Design: Aluminum Chelation

Robert Yokel earned a B.S. in pharmacy from the University of Wisconsin and a PhD in pharmacology from the University of Minnesota. He was on the faculty of the University of Kentucky College of Pharmacy for 42 years. He and his team were developing an aluminum chelation device that was in the conceptual stage for years and overcame development challenges when partnering with Occam Design.

You may find his Q&A and updates on current work below:

1. Before working with Occam, what were some of the roadblocks or limitations you faced?

We were a company of five academics with no entrepreneurial experience. None of us were engineers with experience designing or manufacturing a medical device.

2. How did Occam’s team approach your design differently than you expected?

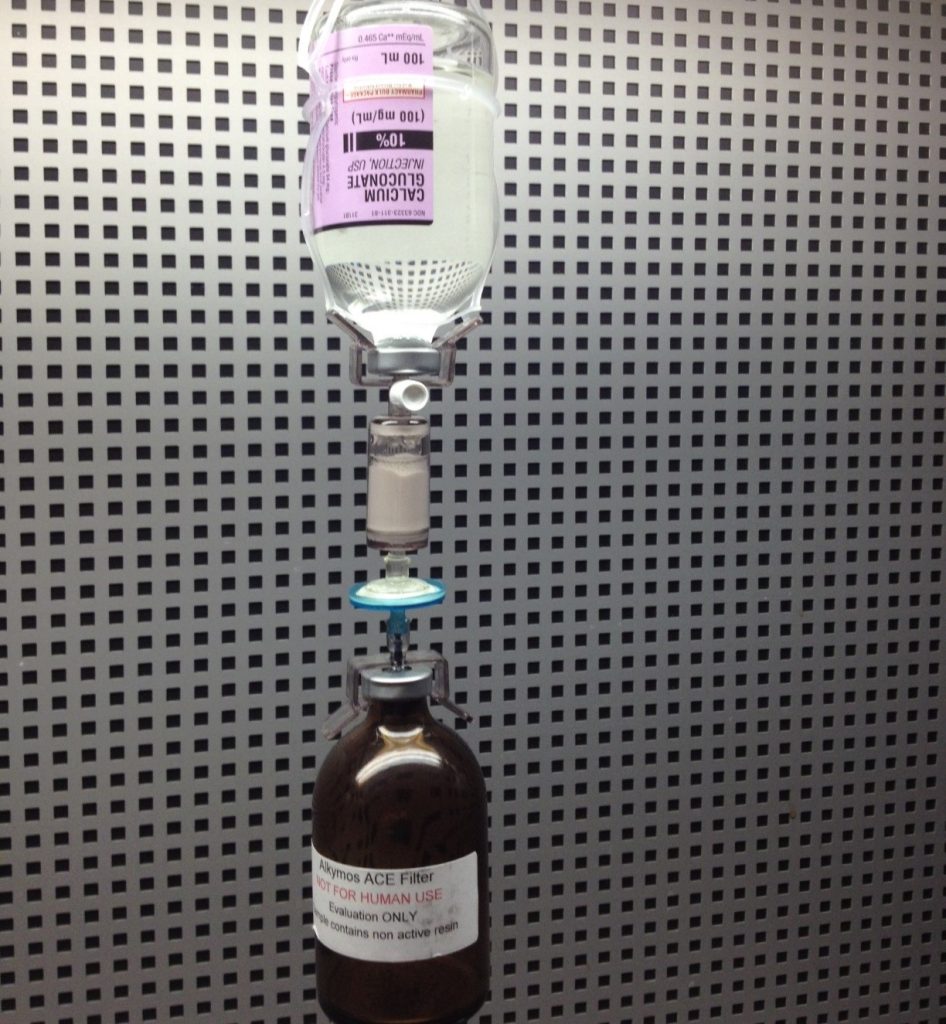

Originally, we intended to create an on-line flow through device. The device was to contain a chelator to remove aluminum within a few seconds as a solution flowed through the device. We found that the reaction rate between aluminum and the chelator was too slow for the chelator to effectively remove aluminum in that time frame. Occam’s team designed an off-line system that included the device containing the chelator, that removed the aluminum from the solution within a longer time frame. This met our goal of removing aluminum from our solution.3.

3. What part of the collaboration with Occam stood out most to you?

The Occam team provided design options we would not have thought of; identified materials, material providers, and fabricators we would not have known how to find; and guidance on the regulatory pathway and requirements for FDA approval for our device.

4. Where can people learn more about your current work or research?

I, and most of my collaborators, have retired. Since retirement, I completed the establishment of a repository of the aluminum concentration in beverages and foods. I am currently compiling data for its first update.