Ever wondered what different 3D printers can offer? Read more to discover the pros and cons of each machine to find the best fit for your printing needs.

3D PRINTING TECHNOLOGY

3D printing technology has revolutionized the way products are designed, prototyped, and manufactured. With a 3D printer, you can create a physical object from a digital design file. There are several types of 3D printers available in the market, each with unique features and advantages. We have been expanding our collection of 3D printers and now offer four different styles of 3D printers to complete the needs of any project. Our team performed an experiment to compare the performance and appearance of the parts by running all printers side by side.

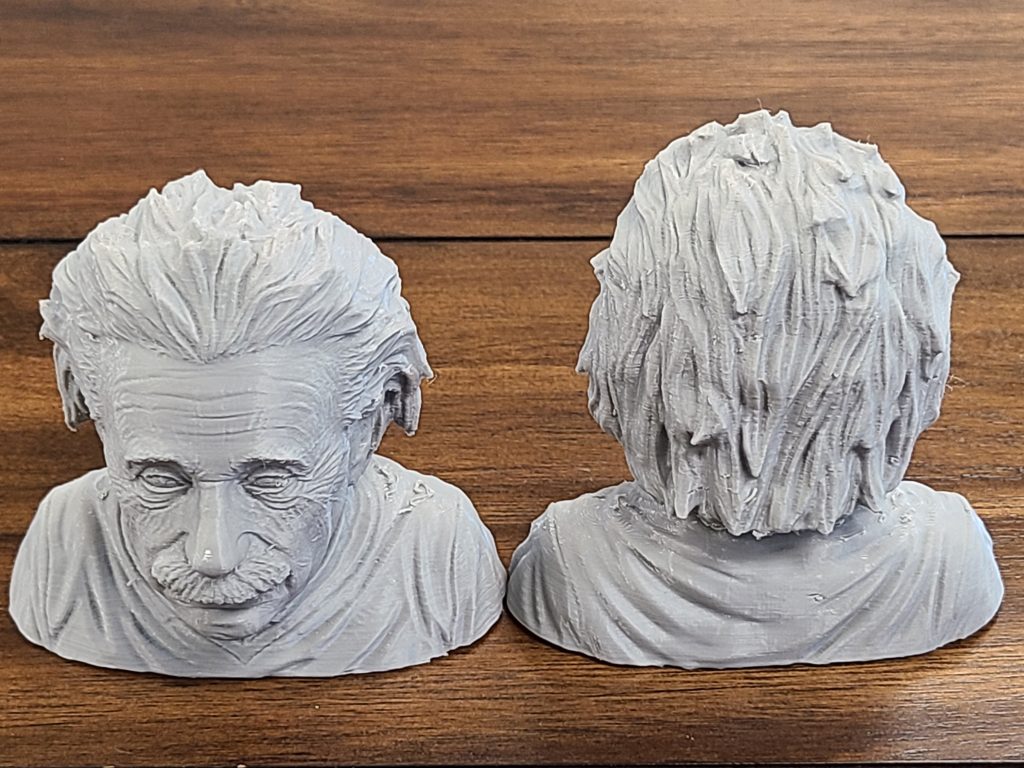

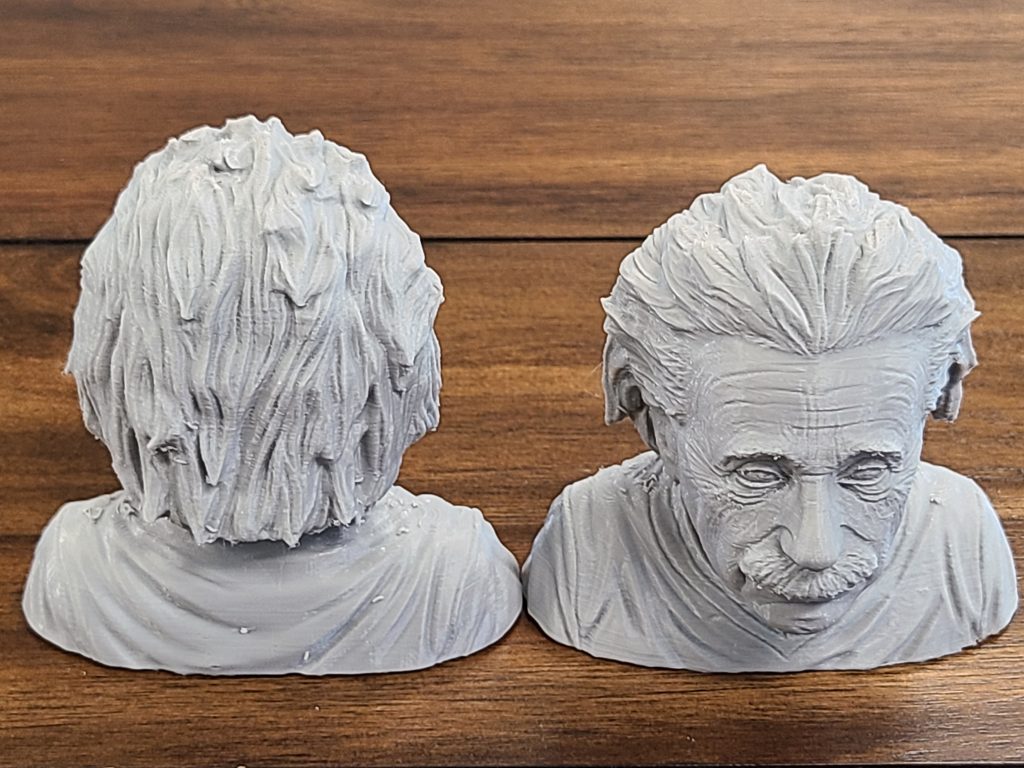

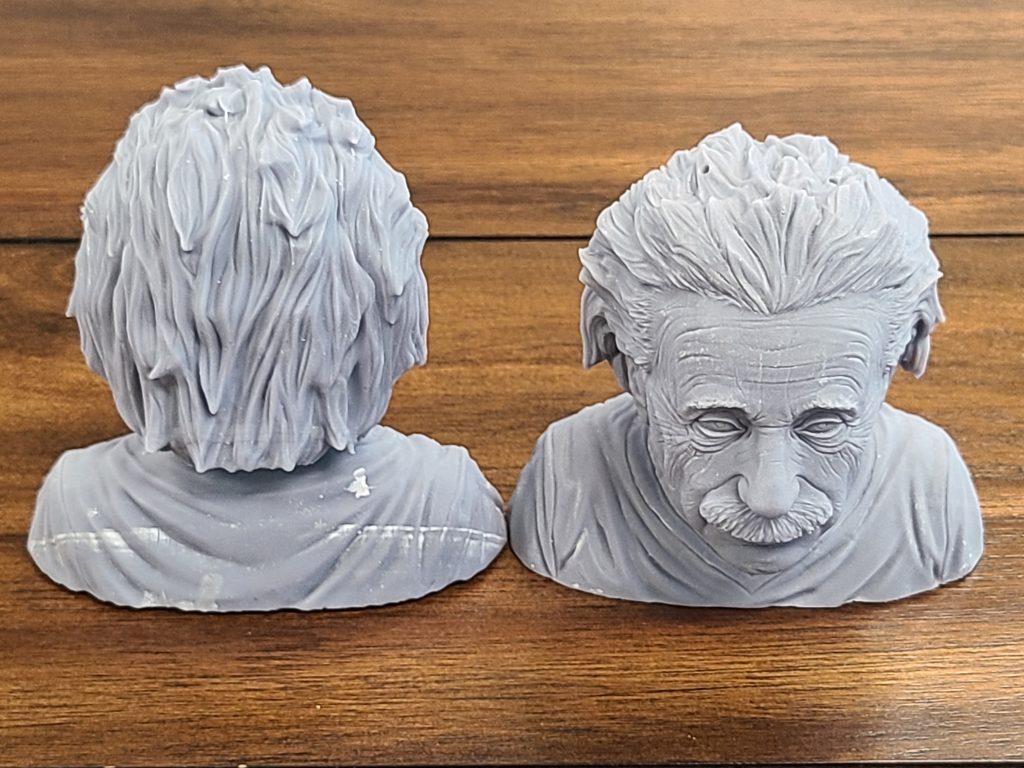

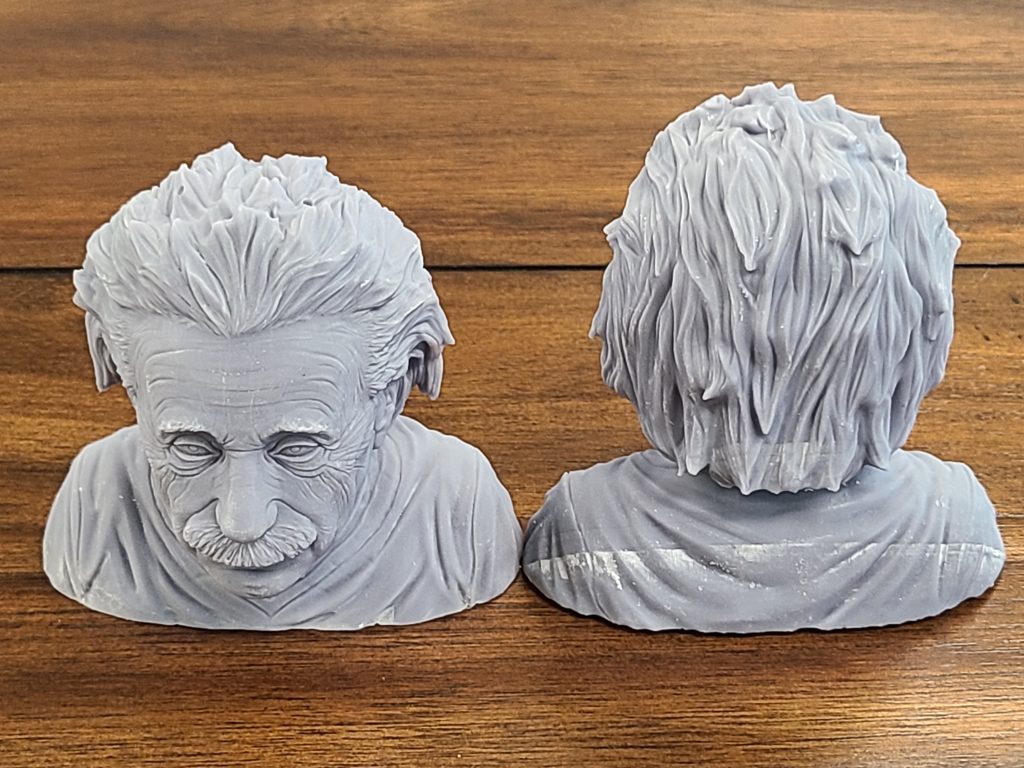

FUSED DEPOSITION MODELING (FDM): TEMPERATURE-CONTROLLED CABINET

Fused Deposition Modeling is the most common type of 3D printer available today. The low cost of materials and affordability of the printer technology makes the FDM printer with a temperature-controlled cabinet ideal for mass adoption. It works by melting a thermoplastic filament and extruding it layer by layer to create a three-dimensional object. Without a temperature control cabinet, larger printed parts have a tendency to warp while being printed. Therefore, having a temperature control cabinet ensures that large parts are printed with the same accuracy as small parts. Parts printed using FDM are usually not solid and have an internal structure, referred to as infill. FDM printers are easy to use, affordable, and can produce objects with good accuracy and strength. However, they have limited resolution and are not suitable for printing complex or detailed objects.

The pros to this type of 3D printer include the ability to change the density by adjusting the pattern of the internal structure of the part. Additionally, the material is relatively inexpensive, the machine can extrude two different materials in one print, and there is a large selection of materials which include ABS, PLA, Nylon, and PETG. However, it is also important to consider the cons as well. These may include slow build speed, visible layers, and low detail resolution. Although this type of 3D printer still has some very important uses, it is considered old technology.

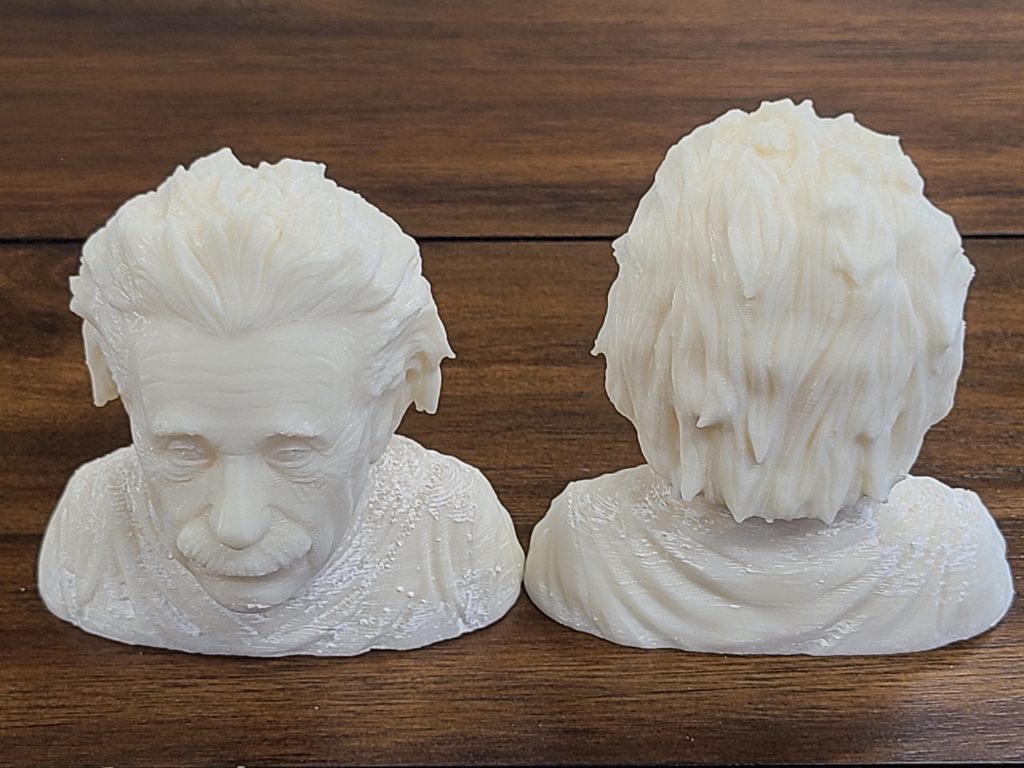

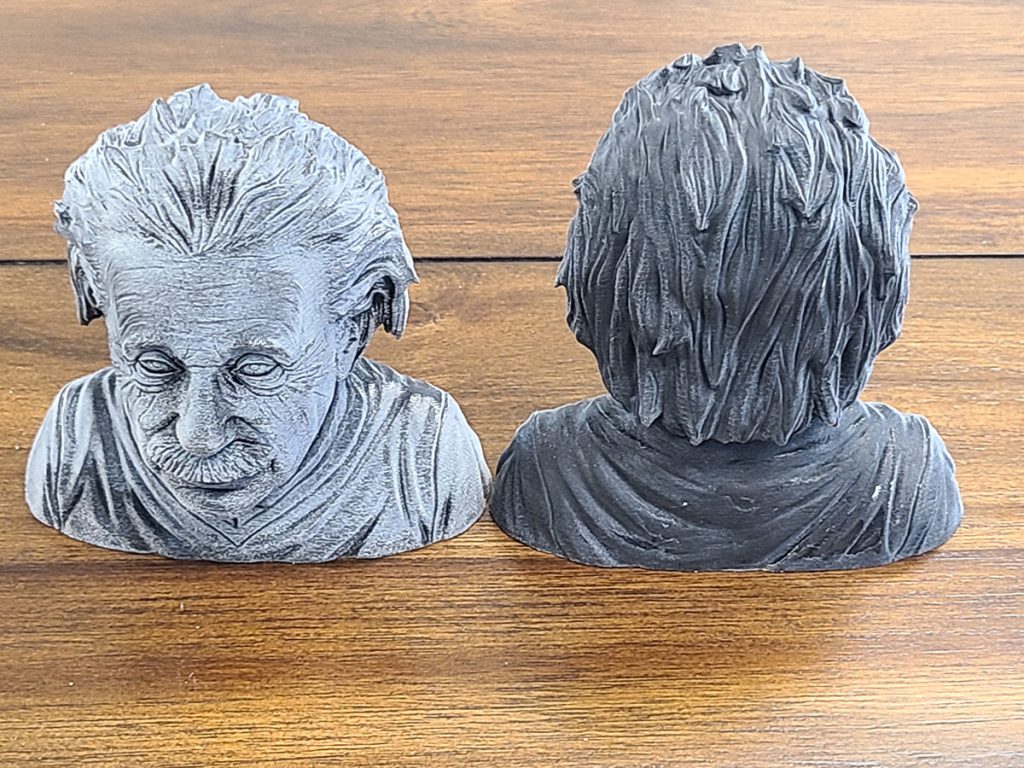

FUSED DEPOSITION MODELING (FDM): WITHOUT TEMPERATURE-CONTROLLED CABINET

Your company may also choose to opt for a Fused Deposition Modeling printer without a temperature-controlled cabinet. It works by melting a thermoplastic filament and extruding it layer by layer to create a three-dimensional object. Same as FDM temperature-controlled cabinets, non-temperature-controlled FDM printers are easy to use, affordable, and can produce objects with good accuracy and strength. It is important to note that they also have limited resolution and are not suitable for printing complex or detailed objects.

The pros to this type of 3D printer without a temperature-controlled cabinet are not as significant as the printer with a temperature-controlled cabinet. However, it still has many benefits, which include the ability to change the density of the part, inexpensive material, and there are upgrades available to improve the quality of printed parts. Cons include the slow build speed, visible layers, low detail resolution, and the fact that it can only build one material at a time. The quality that this machine produces is surprising, and we have determined that it is the best machine we have for our everyday needs.

LIQUID-CRYSTAL DISPLAY (LCD)

Liquid-Crystal Display printers flash complete layers at the resin tank, with the UV light coming from an array of LEDs shining through an LCD screen. This is to ensure that it can cure the liquid resin on each layer to create a solid object. They are similar to SLA printers, but they use different methods to cure the resin. LCD printers are capable of producing high-resolution objects with good accuracy, but they can be more expensive than FDM printers. Cured resin parts are also generally more brittle than parts produced with other 3D printing methods due to the nature of the photopolymer resin required to make the process work.

Pros to this 3D printer include the ability to change the density of the part, the materials are inexpensive, it harbors a very fast build speed, it offers high resolution, there are a large number of different materials available, supports are mostly unnecessary, and it is a very affordable option. The cons of this 3D printer include the difficulty of dealing with messy, liquid materials, and it is crucial that waste is properly disposed of. Additionally, only one material can be used for the model, and parts can be brittle. We believe that this machine would be the best machine to have if it were not for its messiness.

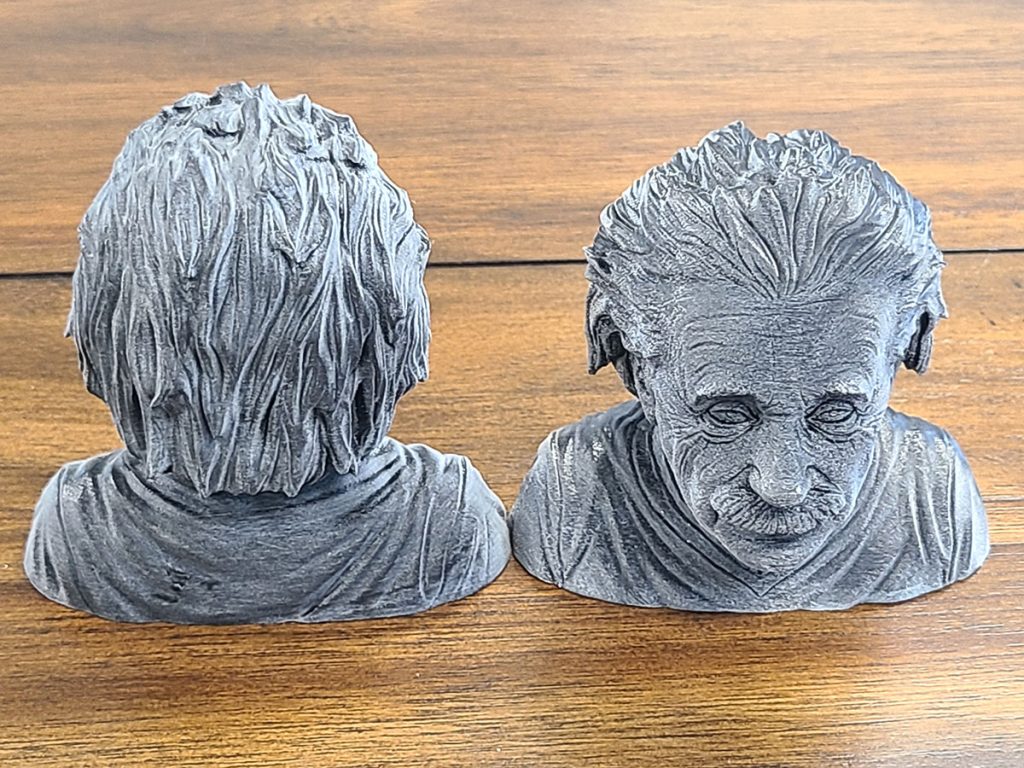

MATERIAL JETTING (POLYJET)

Material jetting printers use multiple print heads to deposit and cure liquid materials layer by layer to create an object. These printers are very similar to a standard inkjet printer. They use print heads to jet material down each layer, which is then cured by a UV light that passes over the layers. They are capable of producing objects with high accuracy and a high resolution. These printers can even print in multiple materials or colors at once. However, they are generally more expensive than other types of printers and require more maintenance.

Using this printer consists of the following pros: high resolution, a large number of different materials are available, the build parts almost look and feel like injection mold parts, the printer can build numerous materials at the same time with different colors and densities, and there is no wasted material involved in the printing process. Cons include the fact that you cannot change the density of the part, the part has to be surrounded by supports, and the materials and machines are expensive. Although this printer is not as messy as the DLP printers, material jetting printers still deal with liquid materials and, therefore, can be a messy process. Overall, this printer has incredible parts, but it is expensive to operate.

Contact OCCAM Design today to learn more about your 3D printing options. With OCCAM, you can be sure that we will provide you with the highest quality products through our top-notch 3D printing services, among our other various medical device development services. When you choose OCCAM Design, you are investing in a hardworking, highly-skilled team to ensure your product performs and functions with excellence.