CREATING AN ELECTRICAL ISOLATION DIAGRAM

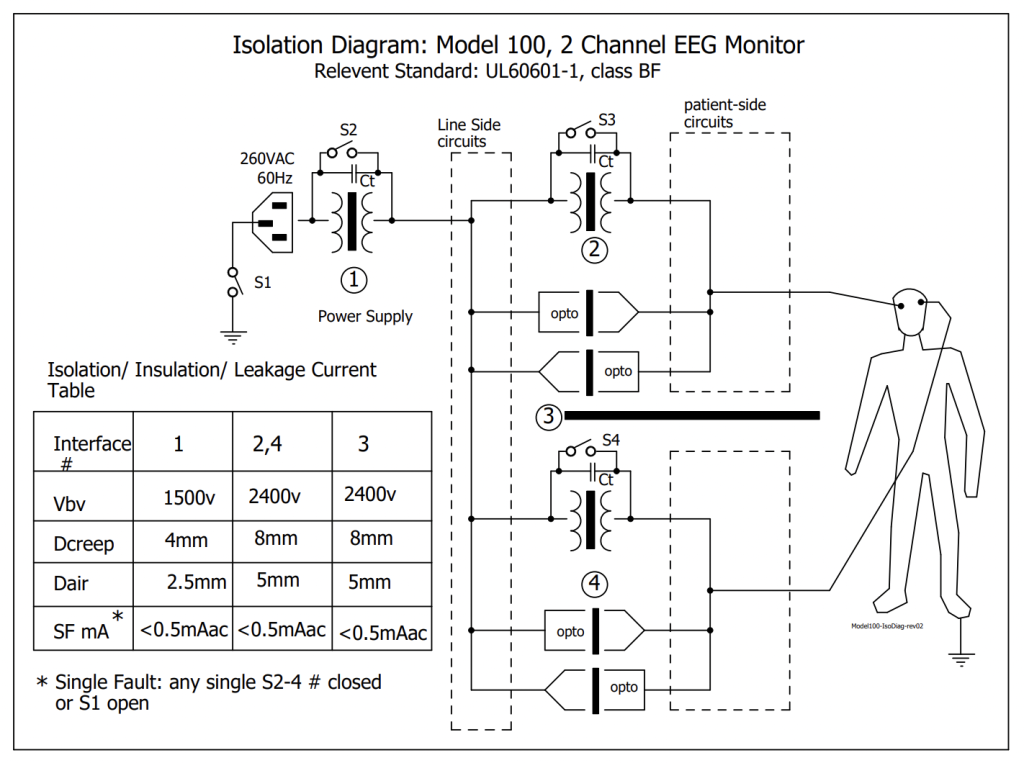

Your electronic medical equipment (often called a “device” by FDA) must meet rigorous electrical safety standards for both operator and patient protection. To assure full compliance, your design company should use a graphical aid technique called an Electrical Isolation Diagram. When we are creating an Electrical Isolation Diagram, the procedure should be simple. The main goal of this process is to establish where the Means of Operator (MOOP) and the Means of Patient Protection (MOPP) are located within the design. That is the purpose of an Electrical Isolation Diagram, to indicate how the patient is isolated from the main and secondary circuits of a product.

The first step is to identify what is considered the patient environment. Any person who will be using the product designed within the isolation diagram must familiarize themselves with the patient environment and other additional information that may be useful to fully understand the product and its intended design. To create a safe product for the patient and the user, all blocks of electronics must have equivalent insulation safety-related compartmentalization into one single load. It is crucial that in each diagram, the creator combines systems that are similar electronically. When all similar pieces are centralized to one part of the device, the creation is up to code and safety standards according to the IEC 60601-1 Safety Standards.

International Electrotechnical Commission, IEC for short, Safety Standards require that industry-known symbols must be utilized when constructing our diagrams, or any Electrical Isolation Diagram. Within Annex J of IEC 60601-1, you can find the outline of all insulation paths on a medical device. It is important to review the diagrams of various insulation barriers between the device and the patient so that you can understand which approach will work best for your unique device.

THE IMPORTANCE OF CREATING AN ELECTRICAL ISOLATION DIAGRAM

We at OCCAM plan your medical equipment device early through the use of a diagram to increase both safety and the reduction of errors. Patient safety is the number one goal in all medical device creation. If we create a diagram early, we allow a window of opportunity that properly allows our team to make necessary changes in the event that a device design changes. With each new change or addition, such as an added circuit or the placement of an electrical outlet channel, we are required to create a new diagram. Our Electrical Isolation Diagram ensures that the device-to-patient channels do not have negative results that circumvent the original design.

After updating the diagram, you can use the initial diagram creation and the new diagram to show your team what the issues were and what you needed to change to maintain patient safety. Not only do Electrical Isolation Diagrams confirm that we are placing a high priority on patient safety, but it also improves our team’s ability to create incredible products for future clients. Through continued learning and the use of the IEC 60601-1, we will ensure that our designs pass all standard requirements and provide you with the best product possible.

As medical device creators and builders, people and companies approach our team at OCCAM with medical devices that are at every stage of development. Creating a diagram is both necessary and important for every client’s process. Whether we are building your device from the initial thought conception, or we are addressing a nearly complete design to determine if all standards are covered, you can guarantee that your product is in great hands. Contact our team to begin saving lives today.